Maintaining your equipment, no matter how large or small the parts may be, is the best way to get the best return on your investment. Pump motor bearings, seals and gaskets are no exception. Taking preventative measures can minimize wear and tear on your equipment and ultimately save you money, time and effort in the long run.

Maximize your overall process reliability by protecting your gaskets, seals and bearings. Learn more about the importance of pump preventative maintenance.

Preventing Gasket Failure

Approximately 70 percent of the time that a gasket fails, it’s due to improper installation, lack of maintenance, improper hardware or improper gasket selection. When choosing a gasket, for maximum efficiency, you’ll want to select one that contracts and expands at the same rate as the metal in your pump, especially during low or high-temperature thermal cycling. Doing so, helps prevent sealing loss. You’ll also want to minimize damage to your gaskets by using gaskets with higher-sealability that are designed to prevent leaking. When a liquid is present on the sealing surface, chances of the liquid causing erosion to the pump are increased, leading to a corrosive environment for your equipment.

Maintaining Seals

When choosing seals for your equipment, consult with the staff at Dade Pump & Supply to ensure that you’re using the proper seals. In most cases, seals are inexpensive, but are crucial to maximizing the efficiency and life cycle of your pump/motor.

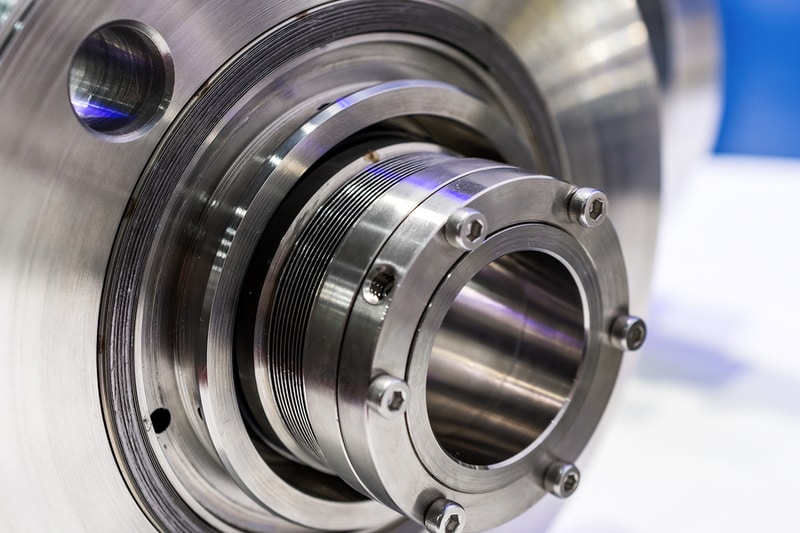

Preventative Maintenance: Pump Bearings

For pump bearings to operate properly, it’s essential that you routinely examine any changes in the lubrication, vibration, temperature and noise of the pump/motor. Many factors affect the performance of pump/motor bearings, such as the environment, speed, loading and lubrication. By taking notice of changes, you can prevent damage that could extend well beyond the pump/motor bearings.

To start, consider the noises coming from a pump/motor. As an industry professional, you’re likely familiar with the ordinary sounds that come from your pump system. Take the time to evaluate any unusual sounds, especially when your system is not operating at its optimal level. Many times, you will hear uncharacteristic noises from pump/motor bearings if there is damage, poor lubrication, contamination or excessive clearance.

If you notice vibration with your pump/motor bearings, it’s likely caused by an imbalance, misalignment or play. Use standard practices to evaluate the vibrations, such as recording the vibration data and vibration acceleration. It’s common for pump/motor bearings to have an increased magnitude of vibration when the bearings are damaged or worn.

Measuring the temperature of a pump/motor bearing is also an effective strategy to determine its condition. In addition, nowadays most pump/motor bearings are sealed and do not require lubrication. Before pumping grease into your bearings please consult with the staff at Dade Pump & Supply as this could cause failures due to excessive grease buildup in the motor windings.

Evaluating, assessing and troubleshooting problems with gaskets, bearings and seals can significantly impact how well your system operates. While these parts may not be large components, they play a vital part in your system’s overall efficiency. Preventative maintenance and routine assessments are crucial to extend the life of your equipment and the staff at Dade Pump & Supply is here to assist with your service needs.

Contact Dade Pump and Supply Today

Dade Pump & Supply is a distributor for the industry’s leading manufacturers of electric motors, centrifugal pumps, hydraulic pumps, irrigation pumps, and pool pumps used in South Florida and the Caribbean. We supply pumps for purposes, including but not limited to agriculture, pools, industry, residential well water, irrigation, flood control and commercial buildings. Please submit a quote request for pricing on replacement/new bearings and installation. We will fix your pump or motor in shop or send a technician to your location (for larger industrial pumps and motors).